Products

Contact Us

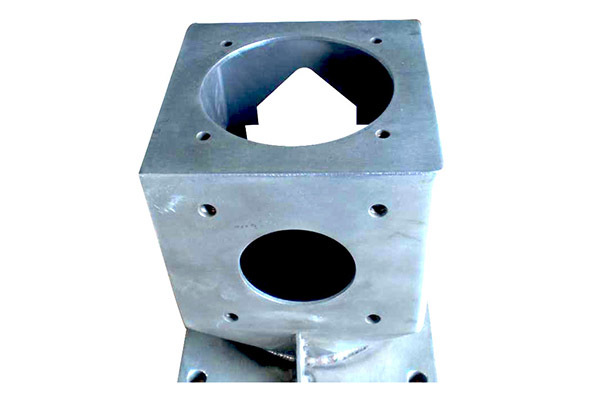

Welded parts

- Commodity name: Welded parts

- Description

-

The micro-deformation and process stability control during the gear processing is relatively complex. Most of the blanks require isothermal normalizing after forging to obtain good processing performance and a uniform metallographic structure of trend deformation; for low-speed network column gears with low precision requirements, teeth can be shaved before heat treatment and no further processing is needed after heat treatment. The application of radial shaving has expanded the range of shaving applications.

There are two methods for post-heat treatment processing of cylindrical gears: honing and grinding. Honing has a low cost but weak tooth shape correction capability, while grinding has high precision but is costly; using tooth top trimming along the tooth height direction and drum-shaped tooth shaping along the tooth length direction can significantly reduce gear meshing noise and improve transmission performance, making it a widely studied area.

Message

Please provide the following valid information and we will contact you as soon as possible.