Products

Contact Us

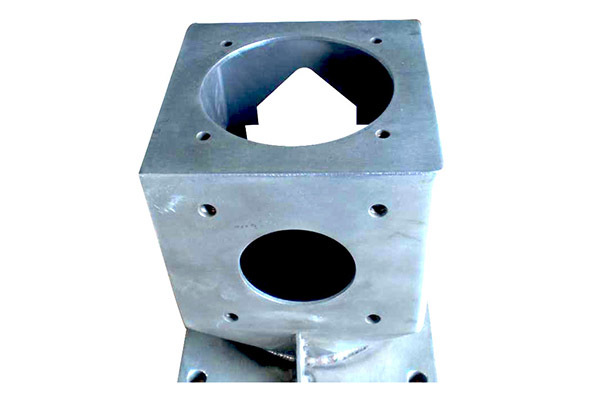

Axis type

- Commodity name: Axis type

- Description

-

One method of gear processing is the forming method, which uses a forming milling cutter that matches the shape of the tooth slot exactly to cut the tooth shape, such as gear milling; the other method is the generating method, which uses the mutual meshing motion of the tool and the passive gear to cut the tooth shape, such as hobbing and shaping (demonstrated with hobs and shaper cutters). Below is an introduction to the method of processing gears using a milling machine. Cylindrical spur gears can be machined on a horizontal milling machine using a disc milling cutter or on a vertical milling machine using a finger milling cutter. Here, we take a cylindrical spur gear with z=16 (i.e., 16 teeth) and m=2 (i.e., a module of 2) as an example to introduce the milling process of gears.

1. Check the gear blank size

Mainly check the diameter of the pitch circle, which facilitates adjusting the cutting depth by increasing or decreasing it based on the actual pitch circle diameter, ensuring the correct tooth thickness on the pitch circle.

2. Gear clamping and correction

Message

Please provide the following valid information and we will contact you as soon as possible.